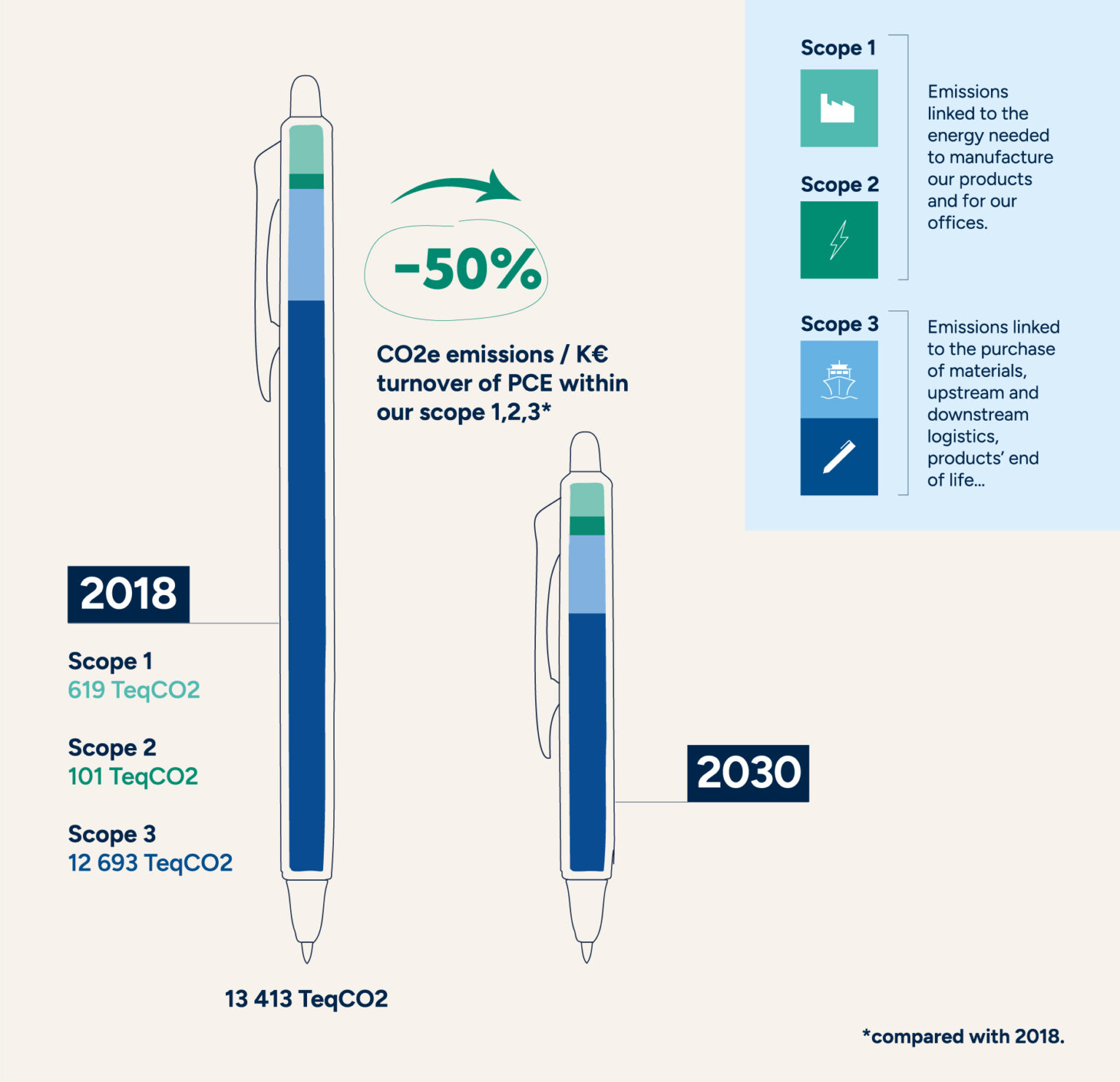

reduce our operation's

environmental footprint

Our target :

-50% emission by 2030

Monitor risk among our value chain

and direct purchase towards

responsible sourcing.

The Responsible Procurement Policy is vital to our CSR approach, reflecting our commitment to integrate sustainable development principles across all business lines and promote them in partner relations.

Monitor risks among our value chain

71% of our suppliers have completed the self-evaluation form on CSR

Promote partnerships relations

We work closely with our suppliers and we favor long term relations with our suppliers and we prefer to select local suppliers.

53% of our packaging operations are done by persons with disabilities.

Direct our purchase towards responsible sourcing

We integrate in our tender minimum requirements on environmental criterias:

- 70% recycled content for cardboard

- 50% recycled plastic

Select the suppliers that are aligned with our responsible purchasing commitments

We asked our supplier to sign our responsible purchasing charter. In 2023, 65% signed it.

Assess & minimize our

production impact

We focus on key environmental impacts like waste, energy, and C02 emissions, closely monitoring and implementing efficient circular processes.

Environmental certified site

Our production site, located in France, has set up an environmental management system.

Saving energy in production

Our new electric presses have enabled us to cut energy consumption by 40% kW/press.

Our European factory uses 100% renewable electricity mainly from hydroelectric origin.

Reduce, reuse, recycle waste

Whenever possible we reduce and reuse our waste. Today, our recycled rate is at 85.3%

Between 2018 and 2024: -20% quantity of waste by product.

Pilot Corporation of Europe, located in France, in compliant with the legislation about plastic granules pollution limitation

Water savings

In term of water savings, the plant retrats its process water in a closer loop system and has installed a rainwater collection tank.

Optimize our supply chain and

minimize its impact.

We are conscious of the major environmental impact of transport in our processes, and have thus set up an ambitious program for the optimization of our product flows

Optimising our logistics flows

The optimization of transport and stock volumes is key to the reduction of our CO2 emissions.

Between 2018 and 2024; we emitted almost 10 times less CO2 emissions to transport our products and components from Japan to Europe.

Choosing more sustainable transport options

We are now deploying barge or rail transport for deliveries from harbors, in order to limit pollution from trucks.

67% of our containers are transported by barge/rail, as against 52% in 2022.